Vertical storage

For vertical storage of long goods, such as sections, tubes, rods or strips, an OHRA vertical rack is the best solution. For vertical storage of chipboard sheets, the chipboard sheet rack is the first choice, particularly in cutting applications of wooden products. OHRA provides vertical racking systems for a large variety of applications and various industries. Vertical racks and chipboard sheet racks are an integral part of storage technology, particularly in carpenter’s and woodworker’s shops, as well as specialised wood shops and DIY shops.

OHRA vertical racks – optimum vertical storage

Vertical racks by OHRA are used in applications where different types of long goods, particularly strips or tube sections need to be stored in vertical position. These may be supply racks, directly at the workplace, but also presentation racks in showrooms where various designs, dimensions or colour options are to be presented in a customer-friendly manner. The robust design of the rack uprights and transverse beams in tried and tested steel structures are also intended for high loads and are not prone to tilting. Depending on the type of applications, the racks may be delivered either as single - or as double-sided racks. The standard heights of the vertical rack are 2,100, 2,700 and 3,300 mm. They are applied depending on the goods to be stored. The useable depths are 450, 650 and 850 mm, the standard bay widths supplied by OHRA are 1,500 or 2,000 mm. For other dimensions, please send us a request.

OHRA vertical racking - your benefits

- Storage of long goods, such as tubes, strips, sections or rods, directly at the workplace

- Option for subdivision by means of separating brackets or separating arms for fast and direct access to the product

- Customer-friendly presentation in the sales area

- Delivery including fixing materials, foot and side cover panels, as well as anchorage options

- Good overview, compact storage, fast and easy access

![[Translate "International (English)"] chipboard racking](/fileadmin/media/products/vertikalregale/_square_preview/plattenregal01.jpg)

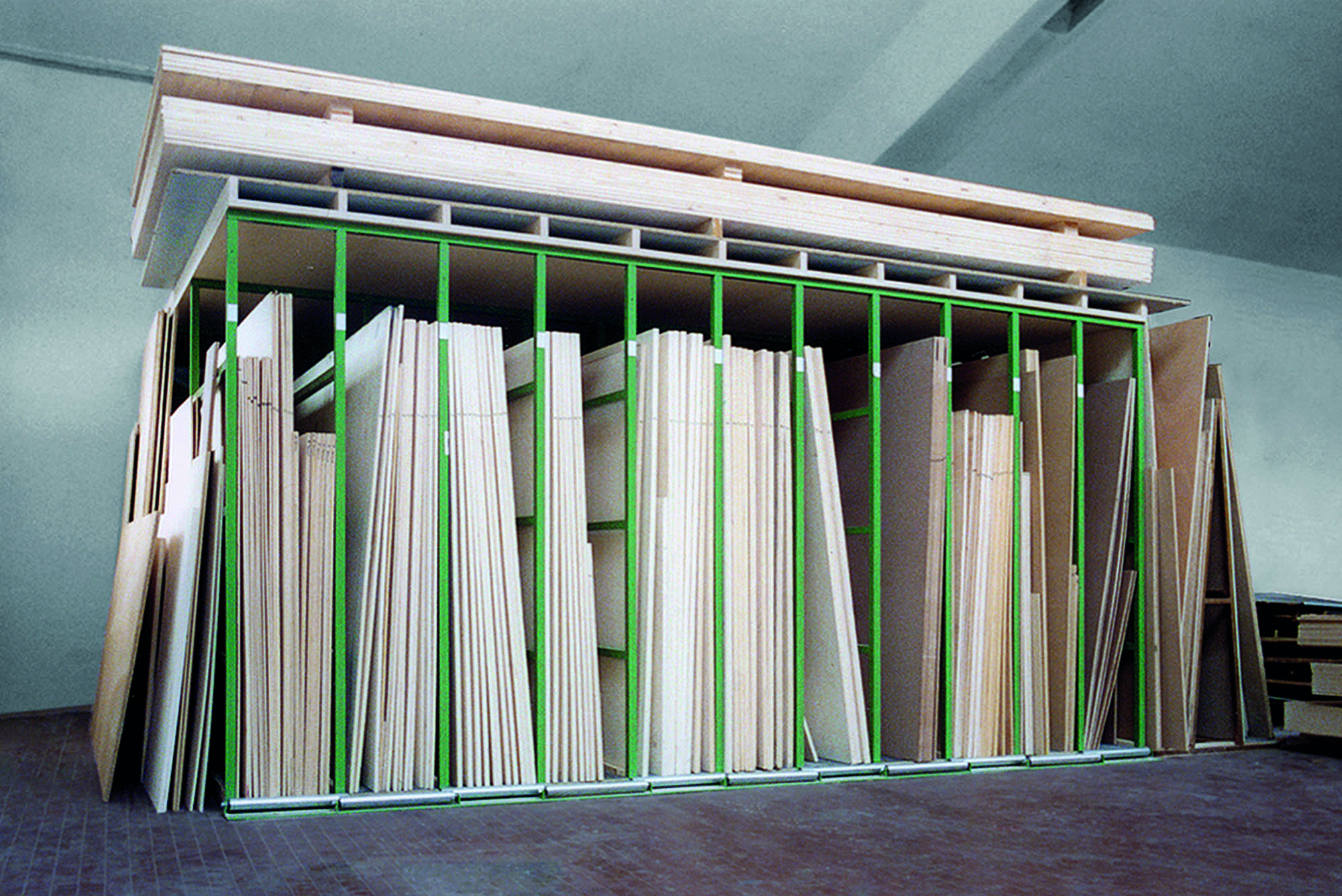

Chipboard sheet racking

A special OHRA product is the sturdy chipboard rack for vertical storage of chipboard sheets and materials in various qualities and dimensions. The sturdy racking system guarantees high bearing loads and fast handling in the workshop.

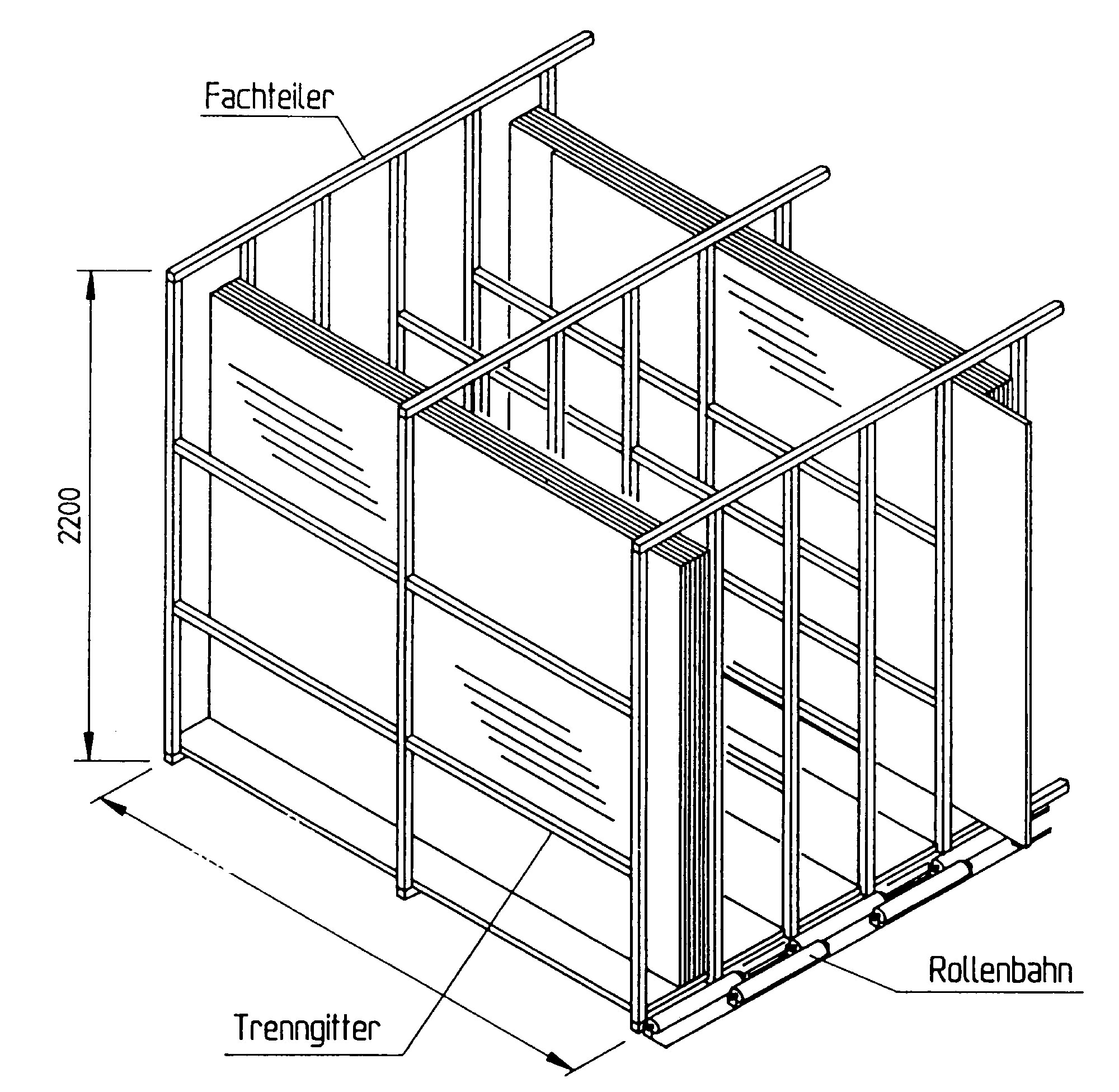

OHRA chipboard sheet racking – varied models

The OHRA chipboard rack is available in 3 different depths. 2,500 mm, 4,000 mm and 5,000 mm. The clear bay height is 2,200 mm. In this way, all conventional chipboard panel sizes can be vertically stored in the rack. The clear bay width is 400 mm. The rack can be ordered as a modular system comprising the base and attachment elements with either 2 or 3 bays. The surface finish is a high-quality powder coat. In addition, the top side of the chipboard plate rack can be covered with a chipboard plate, which can then be used as additional storage area with a surface load of up to 380 kg/m².

OHRA chipboard plate racking - your benefits

- Fast and easy assembly due to modular design

- Subdivision in base and attachment fields for a large number of bay widths

- Top rack level can be used as storage area by using appropriate accessories

- Including roller conveyors in front of every bay for easy storage and removal

- Optionally extendable

- Optimum price-performance ratio